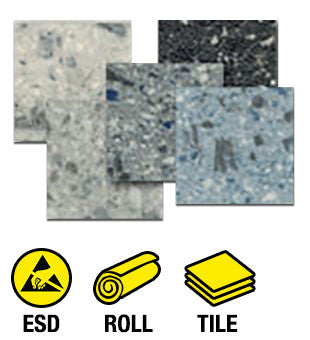

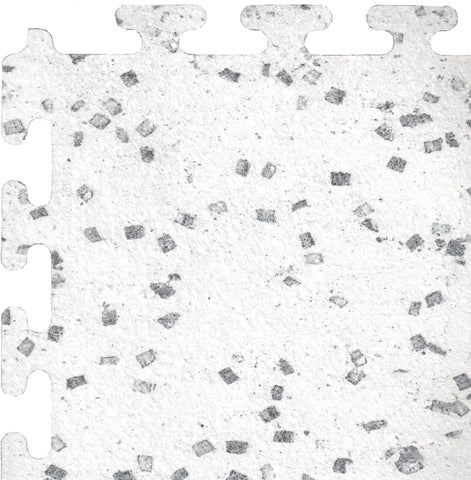

ESD Unifloor® Static Dissipative Vinyl Sheet Flooring

Availability

Rolls 1.5m x 25m (length varies) (5’ x 82’6” length varies). Thickness 2mm (.080”)

Description

ESD static dissipative Unifloor™ is a semi glossy permanently dissipative solid vinyl industrial flooring product with a full surface conductive backing. Roll goods may be used as mats. Alternately they may be permanently glued down and heat welded

Installation

Concrete sub-floors must be constructed as perAmerican Concrete Institute 302.2 “Guide for Concrete Slabs that Receive Moisture Sensitive Flooring” and prepared according to ASTM F710 “Standard Practice for Preparing Concrete Floors to Receive Resilient Flooring”.

Sub-floors must be tested for moisture prior to installation.

- Test per ASTM F 1869 “Standard Test Method for Moisture Vapor Emission Rate of Concrete Sub- floors Using Anhydrous Calcium Chloride ” One test should be conducted for each 1,000 s . Moisture limits are < 3.0/lb./1000 s . in 24 hours.

- Test per ASTM F2170 “Standard Test Method for Determining Relative Humidity in Concrete Floors using in-situ probes. Moisture Limit is < 80% Relative Humidity.

- The pH of the sub-floor should be between 7-9

If these values area exceeded the installation must be halted until corrective measures are taken.

Corrective measures may include additional curing time for the slab, or bead blasting and installation of epoxy water barrier primers. Tek Stil Concepts, Inc. does not provide warranties for such primers, which however may be warranted by their manufacturers. Subfloors must be free of paint, oil, dirt, or any foreign substance. Subfloors must be firm, smooth and even, without cracks. For installation with liquid conductive acrylic adhesive UZIN KE 2000 SL, subfloors must be an absorbent concrete (or absorbent primer over steel; troweled concrete, plywood, or other factory approved surface). Subfloor must be constructed in such a way that moisture cannot seep through and damage adhesive or flooring. Seams of glue-down roll goods must be heat welded to prevent shrinkage. Welded seams shall not exceed 2.5mm (.0 10") at their widest point, and shall be V-groove routed to 70% of depth. Heat welding provides ultimate dimensional stability and monolithic installations which are sanitary, have bacteriological and cleanroom properties, as well as chemical resistance and surface moisture resistance and prevent penetration of dust, bacteria, or chemicals into seams. Liquid welds are not approved for floor Unifloor™ installations. Sigaway Electronic self-stick full surface textile reinforced dry adhesive may be used when installing ESD static dissipative Unifloor™ over concrete, or over non-absorbent existing flooring such as asbestos,vinyl composition tile, wood, fiberglass, epoxy or metal. Follow detailed installation instructions and make a test patch prior to installation.